ICT test fixture is the abbreviation of InCircuitest test fixture, which is an online detection and test fixture. It is a standard test equipment that tests the electrical performance and electrical connection of online components to check manufacturing defects and component defects.

It is mainly used to check the open and short circuit conditions of individual online components and various circuit networks. It has the characteristics of simple operation, fast and rapid, and accurate fault location. The ICT test fixture can perform analog device function and digital device logic function tests, with high fault coverage. A special needle bed needs to be made for each single board. This needle bed is called ICT test fixture in industrial production.

ICT online tester generally refers to the test after PCBA is powered on, mainly including voltage, current, power, power factor, frequency, duty cycle, brightness and color, character recognition, sound recognition, temperature measurement, pressure measurement, motion control, FLASH and EEPROM burning and other test items.

Information and communication technology (ICT) is an umbrella term that covers all communication equipment or application software and various services and application software related to it, such as video conferencing and distance learning.

Information and communication technology (ICT) is an umbrella term that covers all communication equipment or application software: for example, radio, television, mobile phones, computers, network hardware and software, satellite systems, etc.; as well as various services and application software related to it, such as video conferencing and distance learning. This term is often used in a specific field, such as ICT in education, ICT in health care, ICT in libraries, etc. This term is more commonly used outside the United States.

The European Union believes that in addition to its technical importance, the more important thing about information and communication technology (ICT) is that it gives economically backward countries more opportunities to access advanced information and communication technologies. Many countries in the world have established organizations to promote information and communication technology because people are afraid that if countries with backward information technology do not seize the opportunity to catch up, with the increasing development of information technology, the economic gap between developed countries with information technology and underdeveloped countries without information technology will become larger and larger. The United Nations is promoting the ICT development plan worldwide to bridge the information gap between countries.

Back to the original topic, in terms of ICT testing, the strengths of each company are different, but Shenzhen Qianbaishun carefully produces ICT to give users the best experience. At the highest time, the technology can detect 39 pieces of data. The specific bosses can come to check the performance of the machine.

Regarding after-sales, you can rest assured that one-time cooperation is a lifelong cooperation. The workshop is all produced with high-precision technology, grasping the principle of safety, adhering to the concept of continuous development, technology and international benchmarking, and giving the SMT industry enough trust and support.

The testing principle of ICT is to use a needle bed to connect the test points arranged on the circuit board to achieve the testing purpose. ICT must use needle points to be placed on the test points extended from the contact feet of all parts to measure resistance, capacitance and voltage.

1. Short circuit, wrong parts, missing parts, monument, bridge, reverse polarity, etc.;

2. Measure resistance, capacitance, inductance, diode, voltage regulator diode, relay, IC, connector and other parts.

3. Electrical function test.

4. Test the function of active parts.

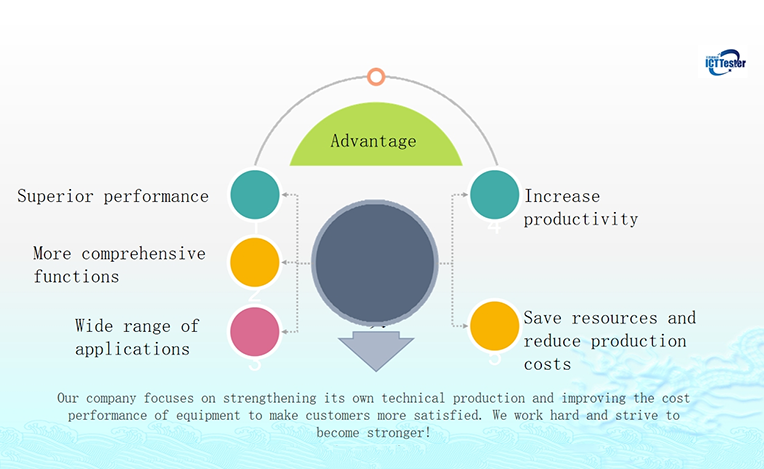

Advantages of ICT testing pcba circuit boards:

1. Fast test speed and short time

PCBA can do L/C/R/D test without powering on, which can effectively reduce the waiting time for test startup and reduce the accident of circuit board burning caused by short circuit

2. Excellent retestability

Controlled by computer program, it greatly reduces the risk of misjudgment and missed test, and reduces the trouble of production line.

3. Product maintenance cost is greatly reduced

The operator can be responsible for product maintenance work, effectively reducing labor costs. ICT can tell which part has a problem through a computer program.

4. Improve product quality

As long as there are enough test points, ICT can measure all the circuits and parts on the circuit board, which can improve product quality

1. The cost of ICT equipment and fixtures is generally more expensive, especially pneumatic steel fixtures, which are more suitable for mass-produced products.

2. When using ICT testing, additional test points need to be designed on the circuit board for the needle bed to connect to. Reduce the utilization rate of circuit board wiring.

3. The needle bed needs regular maintenance, and the probe also needs to be replaced regularly to ensure that it and the probe operate normally.

Shenzhen Qianbaishun is a conscientious ICT testing company. Welcome to consult on this issue.