Product Features

1. Equipped with EC jet test technology

2. Design of CMOS + replay switch card

3. True broadband test technology

4. Humanized win7 interface, simple operation and easy to use

5. Powerful board view

6. Five wire test technology, up to four terminal components can be tested

7. ATPD automatic test program debugging

8. Improve statistical analysis reports and effectively monitor production quality

Product Features

1. Equipped with EC jet test technology

2. Design of CMOS + replay switch card

3. True broadband test technology

4. Humanized win7 interface, simple operation and easy to use

5. Powerful board view

6. Five wire test technology, up to four terminal components can be tested

7. ATPD automatic test program debugging

8. Improve statistical analysis reports and effectively monitor production quality

Make Your PCB with high quality

ICT tester (In-Circuit Test) is an automatic testing equipment used in the manufacturing process of electronic products. It is widely used in PCB (Printed Circuit Board) production lines to detect whether the welding, connection and component installation on the circuit board comply with specifications.

1.Equipped with EC jet test technology

2.Design of CMOS + replay switch card

3.True broadband test technology

4.Humanized win7 interface, simple operation and easy to use

5.Powerful board view

6.Five wire test technology, up to four terminal components can be tested

7.ATPD automatic test program debugging

8.Improve statistical analysis reports and effectively monitor production quality

Resistance 0.1 Ω ~ 40M Ω The accuracy is 0.05 Ω~ 100M Ω ( 2-wire) ± 1% - 5% (four wire) 0.05 Ω.

Capacitance 1pf ~ 40MF precision ± 2%-5%.

Inductance 1uh ~ 50h, accuracy 2% - 5%.

Diodes 0.1 ~ 6V accuracy ± 1%-3%.

Stabilized voltage diode 0.1 ~ 15V precision ± 1%-3%.

Measurement of VCE saturation voltage at three terminals of transistor β value.

Three terminal test of field effect transistor VDS, CDs, RD (on).

Optical coupler and relay, with four terminals to test its conduction voltage or resistance.

* The data is obtained under ambient temperature of 25℃ and humidity of 60%

* I.C.T keeps working on quality and performance,specifications and appearance may be updated without particular notice.

Ask a Question: What is ICT tester?

Professional answer: ICT (In-Circuit Test System), mainly used for testing assembled circuit boards (PCBA). The "online" here is a direct translation of "In-Circuit", which mainly refers to components on the line. Online testing is a testing technology that does not disconnect the circuit or remove the pins of components. "Online" reflects that ICT focuses on detecting assembly problems of circuit boards by testing components on the line or open and short circuit states.

Ask a Question: What components can the basic functions of ICT tester measure?

Professional answer: Open, short circuit, resistance, capacitance, inductance, diode, IC protection diode test, etc.

Ask a Question: Why use ICT tester?

Professional answer: According to the statistics of the circuit board assembly industry, assembly defects are mainly reflected in welding open circuit, short circuit, offset, missing parts, etc., accounting for more than 90%. Therefore, the principle of online testing technology application is to be able to quickly detect faulty components or assembly defects, and to accurately locate defects and defect classification.

Ask a Question: Can an ICT tester be considered a multimeter?

Professional answer: ICT can be considered an automated advanced multimeter, and because it has the function of circuit isolation (Guarding), it can accurately measure the actual value of each component in the circuit.

Ask a Question: What is the difference between the functions of an ICT tester and a general meter?

Professional answer: A meter is used to measure a single part, while ICT can measure parts on a real board through a needle bed in addition to measuring a single part. However, there are many circuits on a real board, which can easily divide the signal source and divide the voltage, so it is often necessary to add the "Guarding" function to make the measurement accurate.

Ask a Question: What is the relationship between ICT and AOI?

Professional answer: ICT is mainly carried out through electrical measurement methods, while AOI is carried out through optical image processing technology. The two have their own strengths and complement each other. In terms of process arrangement, AOI is generally performed first, followed by ICT.

Check the electrical performance of online components on the manufacturing board and the connection of the circuit network. It can quantitatively measure devices such as resistors, capacitors, inductors, crystal oscillators, etc., perform functional tests on diodes, optocouplers, transformers, relays, etc., and perform functional tests on small and medium-sized integrated circuits, such as all 74 series, memory types, ordinary drive types, switch types, etc.

By directly testing the electrical performance of online devices, manufacturing process defects and component defects are found. For component types, it can check component value tolerance, failure or damage, memory program errors, etc. For process types, it can find faults such as solder short circuit, wrong component insertion, reverse insertion, missing installation, pin lift, cold welding, PCB short circuit, and broken wire.

The tested fault is directly located on specific components, device pins, and network points. The fault location is accurate, and repairing the fault does not require too much professional knowledge. It uses program-controlled automated testing, which is simple to operate and fast to test. The single-board test time is generally a few seconds to tens of seconds.

1. Improve product quality

There must be enough test points. ICT can measure all circuits and parts on the circuit. Parts on the bypass (by pass) can be measured, which can improve product quality, reduce customer complaints, and even improve efficiency.

2. Fast test speed and short time

PCBA can perform L/C/R/D tests without power on, which can effectively reduce the waiting time for test startup and reduce accidents of circuit board burning due to short circuit. A circuit board with 300 parts can be tested in 3~5 seconds at the fastest. Of course, the whole machine working time must be added with loading and unloading.

3. Improve product breeding rate (pass rate)

Through rapid detection, problems are immediately fed back to the front-end SMT operation, reducing product defect rate, reducing inventory inventory and defective product stacking, reducing costs, and improving breeding capacity.

4. Good strictness

Through computer program control and precision detection, the risk of penalty points and missed judgment is greatly reduced, and the difficulty of production line is reduced. (If there is a problem at the detection point, a penalty may be generated)

5. Low dependence on existing technology

Since the entire process is controlled by computer, the operation time and failure rate of personnel are greatly reduced. General operators only need a little training to easily operate the equipment and can change the detection program by themselves. (The detection program must be maintained by professional technicians or engineers).

6. The maintenance cost of agricultural products is greatly reduced

General operating employees can carry out product maintenance work, effectively reducing personnel costs. ICT can determine which components or nodes have problems through computer programs, greatly reducing the speed at which technical employees re-measure defects and troubleshoot.

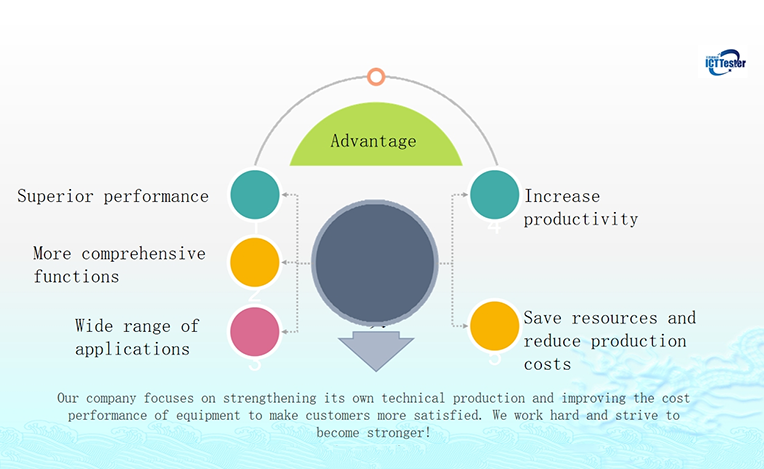

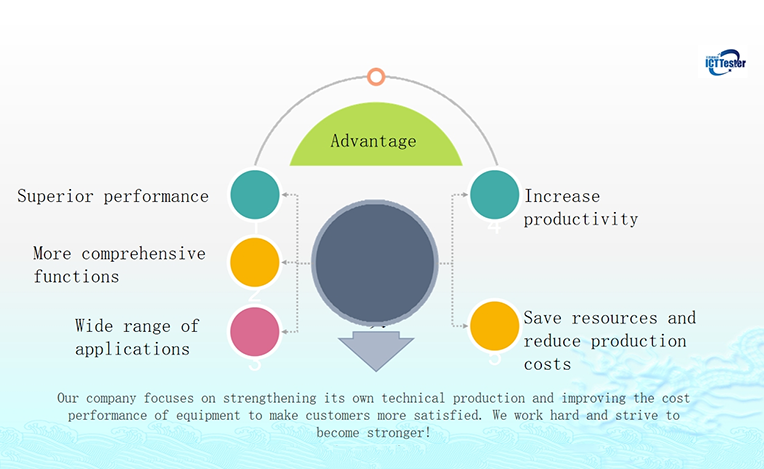

ICT testers are versatile tools that can help organizations achieve a wide range of goals. One of the main advantages of ICT testers is that they can ensure the functionality and performance of ICT systems. By using various testing methods such as functional testing, performance testing, and security testing, ICT testers can help identify any potential problems or vulnerabilities in the system. This proactive approach can ultimately help companies avoid costly downtime and reputation damage.

In addition to ensuring the quality and reliability of ICT systems, ICT testers can also help organizations streamline processes and improve efficiency. By automating the testing of various ICT components, businesses can reduce the time and resources required for testing, allowing them to focus on other strategic initiatives. This can lead to a more agile and competitive business environment, ultimately driving growth and profitability.

In addition, ICT testers can also assist businesses in meeting regulatory requirements and industry standards. With the increasing emphasis on data security and privacy, organizations are under pressure to comply with regulations such as GDPR and HIPAA. ICT testers can help businesses ensure that their systems comply with these regulations, reducing the risk of non-compliance penalties and potential data breaches.

Shenzhen Qianbaishun Technology Co., Ltd. is a professional ICT tester supplier.

We will show you how to improve product reliability while improving performance and reducing costs. Our team of technical support experts will provide your company with reliable global supply, unparalleled efficiency and excellent technical support.

Please contact us at +86-130 6688 1349 or send an email to yuan@szqbs.com.cn

Email: yuan@szqbs.com.cn

Address: Kaihuimao Industrial Zone, Liyuan Road, Fuyong Town, Bao'an District, Shenzhen, Guangdong, China

Post code: 518000